Steel electrodes

A high-quality welded joint must be strong, durable, not corroded and have an aesthetic appearance. These properties are determined by the following factors:

- correctly selected welding mode;

- correctly selected welding material;

- welder's qualification.

The most common welding processes are steel operations due to the widespread use of this material in industry, transport, energy, housing and communal services and in everyday life. Different brands of electrodes are used for welding steel. There are melting and non-melting electrodes. All melting electrodes are a metal rod, the composition of which should correspond as much as possible to the material being welded. During the melting process, the heated electrode material participates in the creation of the seam. Often, the electrode rod has a coating (coating). Its purpose is to protect the welding zone from oxygen penetration and improve the quality of the seam.

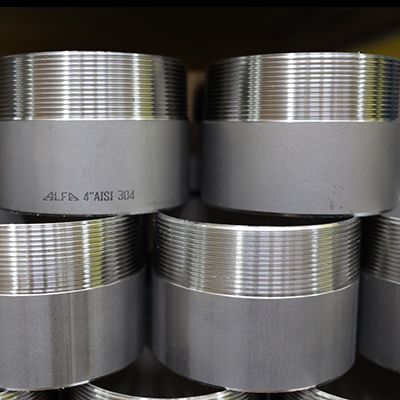

Electrodes for welding stainless steel must have special properties, since this material has relatively low weldability. The use of incorrectly selected electrodes has a dangerous consequence - intercrystalline corrosion - and leads to the destruction of the weld.

Our company offers high-quality material for welding on steel, including stainless steel. Cromarod brand electrodes manufactured by Elga (Sweden) provide a high-quality seam that is not subject to general and intercrystalline corrosion. Their advantages include:

- application for welding materials operating in aggressive environments, including AISI 316 steel;

- stable arc gorenje, thereby forming a high-quality seam;

- the ability to work in vertical and ceiling positions;

- the possibility of welding structures made of thin steel;

- operation on both direct and alternating current.