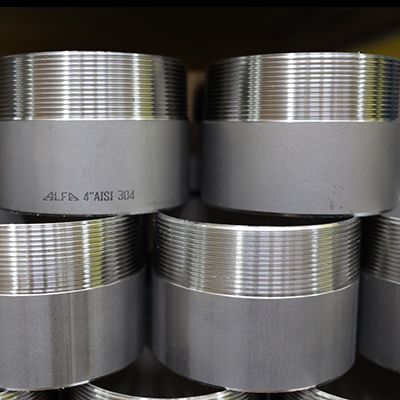

Welded stainless steel fittings aisi 304 and aisi 316

These are the connecting elements of the pipeline. They perform the following functions:

- formation of the medium transportation route in the pipeline (transitions, bends, branches);

- connection of pipes of different diameters;

- connection of various types of equipment (measuring, control, capacitive);

- formation of dead-end sections of the pipeline.

The main task of the fitting is to ensure the strength, reliability, tightness of the connecting node. Stainless parts cope with this better than products made of other materials.

The connection of fittings to the pipe can be detachable (threaded, flanged, etc.) and non-removable (welded). Welded components, in comparison with threaded ones, provide greater tightness and strength of the unit.

ALFA-STAR company supplies welded stainless steel parts of the following types:

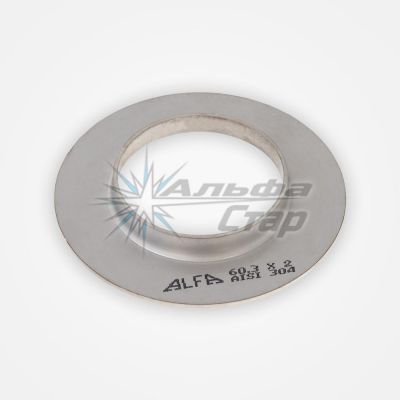

collars for connecting pipes of different diameters, as well as for articulating the end of the pipe with the walls of the medium storage tank (liquid, gas);

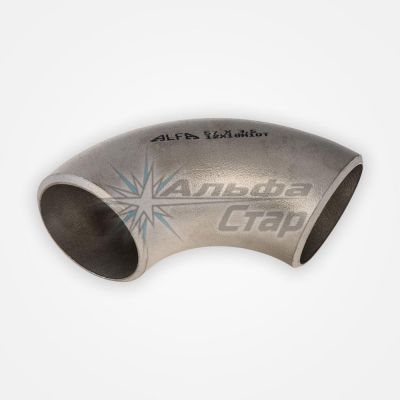

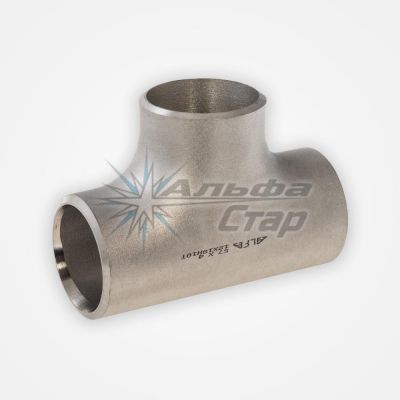

bends, tees and other types of fittings.

The parts can be solid-cast (seamless) and electro-welded. In the latter case, the product is assembled from separate welded fragments. Electro-welded stainless steel bends are used for large diameter pipes.

ALFA-STAR company manufactures and supplies welded fittings made of stainless steel grades AISI 304, AISI 316, which provides high strength, corrosion resistance and environmental friendliness of products. AISI 304 steel parts are widely used in pipelines. Bends, tees, transitions, collars, plugs made of this material will last from 25 to 50 years. For the transportation of media with high aggressiveness at high temperatures, AISI 316 components are used. This steel has a higher resistance to corrosion and temperature changes than other steel grades. Stainless steel parts AISI 316 are used in shipbuilding, transportation, storage of aggressive working environments, as well as in environments with aggressive properties, such as seawater.